381a6159p313 – A Guide to GE Gas- Turbine Spare Parts!

Using the 381a6159p313 gas stop valve transformed my turbine’s efficiency and safety. Its durability and precision give me peace of mind during operations. I highly recommend it for anyone serious about maintaining optimal gas turbine performance.

The 381a6159p313 gas stop valve is an important part of ensuring the safety and efficiency of gas turbines. In industries where reliability is crucial, understanding how this valve works can make a big difference. It helps prevent accidents and keeps turbines running smoothly.

Stay tuned with us as we dive deeper into the world of the 381a6159p313 gas stop valve. In the upcoming sections, we’ll explore its role, benefits, and how it ensures the safety and efficiency of your gas turbine operations. Don’t miss out on the insights that could help you optimize performance and reliability.

Understanding 381a6159p313- An Overview!

What is 381a6159p313?

The 381a6159p313 is a Gas Stop Valve designed by General Electric (GE) for their gas turbine systems. It serves as a crucial safety mechanism by controlling and stopping gas flow when needed, ensuring smooth operations and protecting systems from potential damage.

How It Fits in Gas Turbine Systems?

This valve is strategically placed within the gas flow path of the turbine. Its ability to instantly cut off gas flow in emergencies or maintenance scenarios makes it indispensable. Below is a breakdown of its significance:

- Safety Assurance: Protects turbines from overpressure or gas leaks.

- Operational Reliability: Maintains consistent performance by managing gas flow

Key Specifications of 381a6159p313- Everything You Need to Know!

Technical Details:

- Part Number: 381a6159p313

- Manufacturer: General Electric (GE)

- Material: High-grade alloy steel for extreme durability.

- Pressure Rating: High-pressure applications.

- Temperature Tolerance: Operates under extreme temperatures.

Comparison with Similar Components:

- Highlight what makes 381a6159p313 superior to similar parts in terms of durability, efficiency, and design.

Why 381a6159p313 is Essential in Gas Turbine Operations?

Safety Features:

- Rapid response capability to shut off gas supply during emergencies.

- Prevents hazards like explosions or equipment failures.

Enhancing Efficiency:

- Optimizes gas flow, ensuring turbines function at their highest performance levels.

- Minimizes downtime by providing reliable and durable service.

Cost and Longevity Benefits:

- Reduces overall maintenance costs by extending the turbine’s lifespan.

- Superior materials reduce the frequency of part replacements.

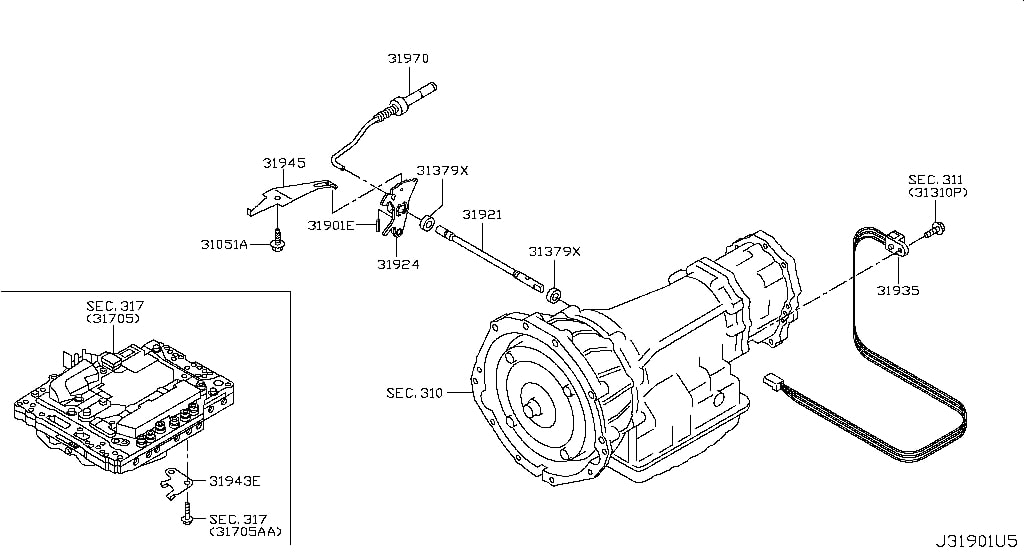

Components and Design Features of 381a6159p313 – Give a look!

Primary Components:

- Body: Made from corrosion-resistant alloy steel, ensuring long-lasting durability in harsh environments.

- Seat: Designed to provide a tight seal, preventing gas leaks and enhancing safety.

- Actuator: Operates the valve either manually or automatically, depending on system requirements.

- Bonnet: Protects the internal components of the valve and allows for easy access during maintenance.

Innovative Engineering:

- Precision Sealing Mechanisms: Crafted for zero leakage, ensuring optimal performance and safety.

- Lightweight Design: Facilitates easier installation while maintaining strength and reliability in demanding operations.

Read: Gravel Near Me – Comprehensive Guide In 2024!

Maintenance Practices for Optimal Performance – Main Need!

Routine Inspections:

- Check for corrosion, leaks, or wear on key components.

- Ensure smooth actuator movement during operation tests.

Lubrication:

- Apply high-temperature lubricants to moving parts to prevent wear and tear.

Troubleshooting Common Issues

- Gas Leaks: Tighten connections or replace seals if necessary.

- Actuator Malfunctions: Ensure proper alignment and power supply (if automated).

Importance of Genuine Spare Parts:

Always use original 381a6159p313 parts to maintain compatibility and performance.

How does the 381a6159p313 valve contribute to turbine safety?

The 381a6159p313 valve plays a crucial role in turbine safety by allowing for the immediate shutoff of gas flow when necessary. This function is vital in preventing dangerous pressure buildups or gas leaks, which could lead to system failures, fires, or explosions.

By ensuring that gas supply can be quickly stopped during emergencies or maintenance, the valve helps to maintain the integrity of the turbine and the overall safety of the system. This quick response capability is essential in high-pressure environments, where even minor issues can escalate rapidly, protecting both the turbine and the operators.

Read: TF Games – Explain Everything You Need To Know In 2024!

Applications and Industry Use Cases of – Key Sectors Using the 381a6159p313 Valve!

Key Industries:

- Power Generation: It ensures the safe and consistent performance of gas turbines that generate electricity. By controlling the gas flow, it helps maintain optimal turbine efficiency and prevents any potential hazards during operations.

- Oil and Gas: In the oil and gas industry, this valve is vital for refining and processing facilities, where gas turbines are often used in compressors, pumps, and generators. It helps manage the flow of natural gas and ensures safe operation’

- Industrial Manufacturing: Many industrial manufacturing processes rely on gas turbines for energy production. The 381a6159p313 valve ensures that these turbines operate smoothly, controlling gas flow and preventing any operational interruptions that could impact productivity.

Real-World Use Cases:

- Power Plants: In power generation plants, the 381a6159p313 gas stop valve is used for managing the gas supply during peak load times. This ensures that turbines operate safely and efficiently, preventing any unexpected shutdowns and maintaining stable electricity production.

- Oil Refineries: In oil refineries, the 381a6159p313 valve helps prevent system failures during high-pressure operations. The valve’s ability to shut off gas flow when necessary is critical for preventing catastrophic incidents and maintaining smooth refinery processes.

Innovations and Future Trends of the 381a6159p313 Valve- What’s Next!

Emerging Technologies:

- Automation: Integration with IoT systems for real-time monitoring and automated responses.

- Blockchain: Tracking and verifying genuine parts like 381a6159p313 to enhance supply chain transparency.

Sustainability Contributions:

- Reducing emissions by improving turbine efficiency and minimizing fuel waste.

- Encouraging longer part lifecycles, decreasing environmental impact.

Read: Nettruyen – Access The Full Picture Effortlessly!

FAQs:

What makes the 381a6159p313 valve a critical component in gas turbine systems?

The 381a6159p313 valve is essential for regulating the gas flow to turbines, ensuring they operate safely and efficiently. It allows for quick gas shutoff in emergencies, preventing potential hazards.

How can I ensure the longevity of the 381a6159p313 valve?

Regular maintenance, including inspections, lubrication, and functionality testing, will help extend the life of the 381a6159p313 valve, ensuring it operates smoothly over time.

Is the 381a6159p313 valve easy to install?

While installation is straightforward for those familiar with gas turbine systems, it is recommended that a qualified technician performs the installation to ensure the valve is properly set up and functioning.

Can the 381a6159p313 valve be customized for specific systems?

Yes, the 381a6159p313 valve can be customized to meet the specific needs of different systems, whether it’s through modifying the actuator mechanism or adjusting its pressure and temperature ratings for particular applications.

How does the 381a6159p313 valve improve operational efficiency?

By regulating the gas flow precisely, the 381a6159p313 valve helps maintain optimal turbine performance, preventing inefficiencies that could arise from improper gas supply management.

Conclusion:

The 381a6159p313 is more than just a spare part; it is a critical component for ensuring the safety, efficiency, and reliability of gas turbine systems. From its advanced design to its broad applications, this valve stands as a testament to GE’s engineering excellence.

For operators aiming to optimize turbine performance, maintaining and utilizing this component is essential.

Read: